What is it, .1 compression point per cc reduction in head volume roughly.

Should put you around 8.8-8.9 to 1 ?

Thats with stock style .045 thick head gaskets?

How much did you deck the block ? "Zero Deck"?

What is it, .1 compression point per cc reduction in head volume roughly.

Should put you around 8.8-8.9 to 1 ?

Thats with stock style .045 thick head gaskets?

How much did you deck the block ? "Zero Deck"?

James Belcher, Jr.

Carolina Trailblazers PR Man

86 CJ 7 401 TF 999 D300

81 CJ 7 360 T 176 D300

85 J20 401 727

To many others to list

James - I take it in your opinion I made a mistake using the stock style pistons.

I don't think so. This is a truck motor for a full size Wagoneer. If I was building for a light weight car, I may have used different pistons. Very soon I will have actual dyno data and if I meet my targets I will be happy.

You are entitled to your opinion. Thank you for your input.

Don

84 CJ7

82 Cherokee

89 GW

its a good build. each of us have different ideas. it is all up to the owner.

keep us posted . will be interesting to see the results.

83 eagle (r.i.p.)

85 gl1200 gold wing LTD pilot

1999 gl1500C valkyrie(plain gold wing)

1994 jeep grand cherokee limited pilot

McDonnell Douglas c-17 mechanic

corrupting people since 1962

Don,

Truely that was not my intention. Iformation about various combinations of AMC is, as you know, not as common as for say an SBC.

I am honestly interested in how you came up with your combination and also how much compression you will have.

In the past I have built several Big Block Chevy's, and I had a good idea to get what I wanted, plus there is a wealth of information available about them. All of the AMC's I have built have been basically stock, with only a cam or intake change.

I currently am doing a 360 for my J20 to tow with and am looking at options.

I also have a 401 I want to build, and am trying to decide exactly what I want.

Thanks for sharing, I support anyone doing AMC/Jeeps.

I'm trying to keep 5 of them going myself.

Again, sorry if I came across like an ass, I just don't mind asking a lot of questions.

James Belcher, Jr.

Carolina Trailblazers PR Man

86 CJ 7 401 TF 999 D300

81 CJ 7 360 T 176 D300

85 J20 401 727

To many others to list

Okay – here is some fun stuff to consider. If you are not a data junkie, just enjoy the pictures. Caveat – I play with cars a hobby, I am not a professional.

This motor is for a daily driver truck that weighs over two tons. A Jeep Grand Wagoneer with a 727 automatic transmission, 3:31 rear gears, and 30” tires. Don’t want to race anyone, just want something better than stock. So the plan was to build for lots of low-end torque, avoid any drivability issues and run on pump gas. Probably never going to go over and will seldom reach 5,000 rpm’s. Taking advice of the pros, emphasis was placed on induction, exhaust, cam, and valve train. Except for the lifter valley oiling mod the bottom end was left pretty much stock after being balanced.

If you look closely you can see where we machined the lifter valley to lay the fabbed up oil line in very low. Tried to use a pre-made kit, just did not like it, too high in the lifter valley.

Also notice we cleaned up the intake ports. As received from Edelbrock, they were rough machine cut with ridges. We smoothed them out and port matched them with the intake manifold. In my experience with other engines, this step alone can gain 20-40 horsepower.

Here is a DeskTop Dyno comparison of stock and the plan. All specs in these calculations are conservative and I expect actual Dyno results to be better.

James wants to know why I did not use the ’71 style 9.5 compression ratio pistons. Sure higher compression increases horsepower. It also creates some drivability issues, namely, detonation and a need for higher octane gas. Not issues you want to deal with in a daily driver. Back in ‘68, I had a ’55 Chevy with a 327 running 10:1 compression ratio with the old Rochester mechanical fuel injection. Ran in high 11’s at over 110 mph in the ¼ mile track. We also had leaded fuel and my driving habits were a little different. Friday nite was race nite in those days and we smoked-em up. Now Friday nite is cruise-in nite and we mostly just show and tell.

I actually considered having custom pistons made. But for the intended use, just did not need that kind of overkill. Could have used the 9.5 pistons but with the smaller combustion chamber heads, I was afraid we would boost the compression too high for the daily driver use. If this was a mistake, we will know next time. Why the Edelbrock heads? Just because they are there, they are new stuff, and sure look nice. The stock heads can be made to flow very good.

I am not really certain of the dish volume of the stock replacement piston for the 401. I used Sealed Power STE415CP, 30 over. Something to consider - I believe suppliers of replacement pistons design them to be a little less compression than the factory spec. Probably to reduce the chance of detonation as most are used in stock applications and increased performance is not an issue. I am told the replacement pistons have a 43cc dish volume. Should have measured it myself, but I didn’t.

Here is a CR calculation using the factory specs. The piston dish volume is calculated using all the other known items (specs from Performance American Style, 1972)

With this information I am guessing the static compression ratio in this build is likely 8.75 to 9. Stock 8.5, some loss on replacement pistons, some gain on smaller combustion chamber with the Edelbrock heads.

Bottom line is this build increases torque and horsepower by making it flow better than stock and using a cam appropriate for the power range and higher compression is not needed to get there.

Don

84 CJ7

82 Cherokee

89 GW

Your closer to 9.0 and maybe a tad under. Nice work on the valley for the oil line! Let me know how she shakes down ok?

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689

Cool, now I am really anxious to see the Dyno results.

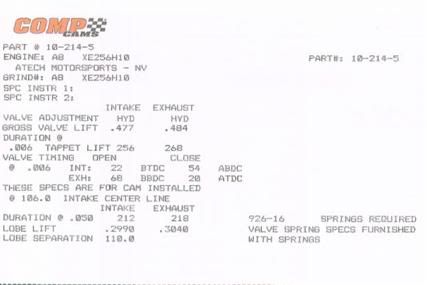

BTW what are tha specs for the cam? I looked on Comp Cams site but could not bring up one for the AMC.

James Belcher, Jr.

Carolina Trailblazers PR Man

86 CJ 7 401 TF 999 D300

81 CJ 7 360 T 176 D300

85 J20 401 727

To many others to list

Cam specs for James

Don

84 CJ7

82 Cherokee

89 GW

Dyno results are finally in.

Did not quite make my torque target of 450. Check out the oil pressure - thanks to MC for the blueprinted timing cover/oil pump.

Don

84 CJ7

82 Cherokee

89 GW

You could have done some fine tuning that may have gotten more hp. I miss the dyno's. Nice looking setup Don!!!!

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689