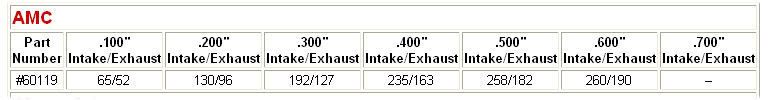

Here is a set of Edelbrock Performer RPM heads for the AMC V8 vs. a set of untouched 3196291-c heads (52cc dogleg heads made in 1970). You will see the ports on the Edelbrock heads are smaller in size when compared to the 291-c heads in some areas, larger in others but offer a smoother port. The Edelbrock's combustion chamber is superior to the stock 291-c's chambers. Edelbrock claims these flow #'s

Intake:

291 090 502 Edel (true numbers)

.100 71 74 70

.200 127 156 143 125

.300 179 201 192 212

.400 209 219 213 235

.500 217 226 220 266

.600 222 232 228 243 (bad turbulence

.700 228 238 236

Exhaust:

.100 55 56 59

.200 107 112 113 98

.300 135 141 146 130

.400 142 145 150 156

.500 145 149 152 174

.600 145 150 153 184

.700 145 151 153 (Edel @ .650 lift .187)

Now we are flow testing these heads as I speak and will post up real world numbers. We will also be doing very basic port work and re-flowing the heads.

Now here we show the port size differences...they are slightly off. Its hard to measure these accurately with a caliper

Reply With Quote

Reply With Quote

at least going by their book numbers.

at least going by their book numbers.