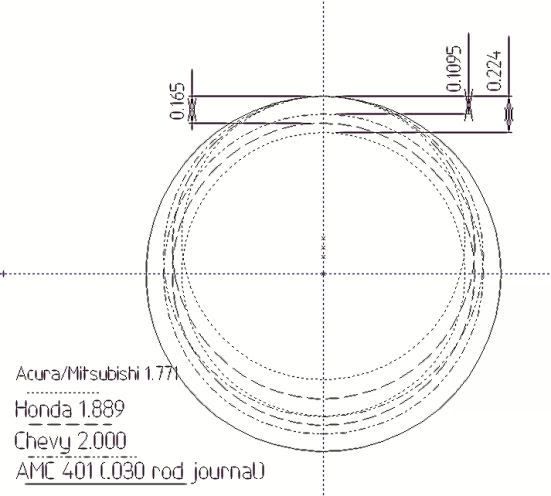

Available as a .dxf as well

4.128 stroke Acura/Mitsubishi bearing 1.771 id

0@450CI

.010@452CI

.020@454CI

.030@456CI

.040@458CI

.050@461CI

.060@463CI

.085 (Big block chevy bore) @468CI

____________________________________________

4.010 stroke Honda bearing 1.889 id

0@437CI

.010@439CI

.020@441CI

.030@443CI

.040@445CI

.050@447CI

.060@450CI

.085 (Big block chevy bore) @455CI

_____________________________________________

3.899 stroke Chevy bearing 2.000 id

0@425CI

.010@427CI

.020@429CI

.030@431CI

.040@433CI

.050@435CI

.060@437CI

.085 (Big block chevy bore) @442CI

These are based off the std 401 bore of 4.165 and using a 401 crank that started at a good cleanup @.030 (after offset grinding) at the top of the journal. This is just a nice reference for those who are thinking of different combos.

Acura/Mitsu journal (4.128 stroke)

6" rod 1.144 compression height piston

6.125" roc 1.019 compression height piston

Honda journal (4.010 stroke)

6" rod 1.203 compression height piston

6.125" rod 1.078 compression height piston

Chevy journal (3.899 stroke)

6" rod 1.2585 compression height piston

6.125" rod 1.1335 compression height piston

Based on a 9.208 deck height (stock 70 and up without any machining done to the deck!)

58cc heads (compressed head gasket = 10cc) = 68cc - 10cc vlave relief

58cc compression ratios

Acura/Mitsubishi (4.128 stroke 30cc dish and 45cc dish)

30cc vs. 45cc dish

0@11.47-9.949

.010@11.5-9.989

.020@11.56-10.02

.030@11.61-10.06

.040@11.68-10.12

.050@11.73-10.16

.060@11.77-10.2

.085 (Big block chevy bore 2.25) 11.89-10.30

Honda (4.010 stroke 30cc dish and 45cc dish)

30cc vs 45cc

0@11.17-9.69

.010@11.21-9.73

.020@11.26-9.77

.030@11.31-9.81

.040@11.38-9.869

.050@11.42-9.909

.060@11.47-9.949

.085 (Big block chevy bore 4.25)@11.59-10.04

Chevy (3.899 stroke 30cc dish and 45 cc dish)

30cc vs. 45cc

0@10.89-9.452

.010@10.93-9.491

.020@10.98-9.531

.030@11.03-9.571

.040@11.07-9.611

.050@11.12-9.65

.060@11.17-9.69

.085 (Big block chevy bore 4.25)@11.28-9.79

Lets say we are looking at a piston for a Blower/NOS application we would want at least a .300 top ring land. We could be looking at a distance of .900" from the bottom of the oil control ring and with a .927" chevy pin and a compression heights of

Acura/Mitsu journal (4.128 stroke)

6" rod 1.144 compression height piston

6.125" roc 1.019 compression height piston

Honda journal (4.010 stroke)

6" rod 1.203 compression height piston

6.125" rod 1.078 compression height piston

Chevy journal (3.899 stroke)

6" rod 1.2585 compression height piston

6.125" rod 1.1335 compression height piston

We are looking at a possible total from top of piston to top of wrist pin to be

.927/2 = .4635 + .9 = 1.3635 (For the lowest possible compression height without having the lower oil control ring touching the top of the wrist pin bore using 5/64 rings .300 top ring land)

Now we know that 1/16 rings are a better choice and are stock on chevy motors and when you use a .927 pin you are in fact using a stock size chevy pin so lets use their better ring choice and recalculate the optimal height.

.927/2 = .4635 + (.9 "at 5/64 ring" - {.0781(5/64) -.0625(1/16) = .0156 * 2 = .0312} = .8688 ) = 1.3323 (For the lowest possible compression height without having the lower oil control ring touching the top of the wrist pin bore using 1/16 rings .300 top ring land)

Acura/Mitsubishi 1.144 compression height 6" rod the oil control ring groove enters the wrist pin bore by .1883

Honda 1.203 compression height 6" rod the oil control ring groove enters the wrist pin bore by .1293

Chevy 1.2585 compression height 6" rod the oil control ring groove enters the wrist pin bore by .0738

Now I do know Chevy LS1 (NOS/Blower application), Chevy small block (NOS/Blower application), BBC (nitrous domes), Ford Boss 302, and Ford big block 385 all use oil control grooves entering the wrist pin bore so I dont see an issue there.

Reply With Quote

Reply With Quote