Well the last three days have been long, 15+ hrs

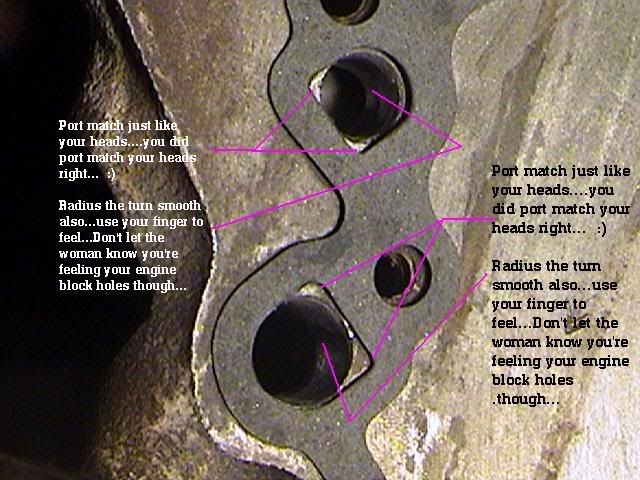

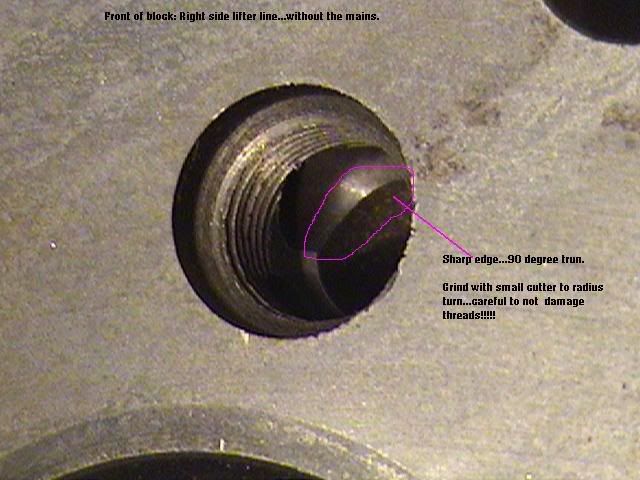

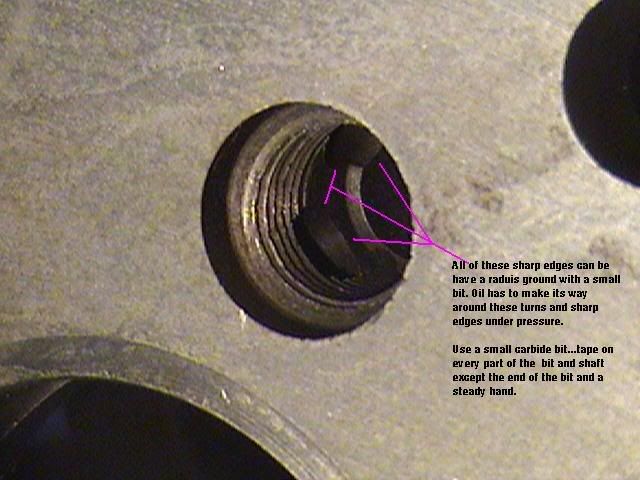

I have just about learned all I ever will about the newly built engine, FAST ECU, timing, retarding The need to take time building a engineand using the best parts. I have learned all I can about the infamous AMC engine oiling mods, Bulltear/Crown timing covers, 534 plates, oil pump gears, gaskets, the valley bypass line, and oil pressure drops in the system. (Interesting findings there I can tell you!!!)

I have many opinions, observations, and factual data to sift thru.

Not many pics or video as I was usually oily, dirty and just straight out modifiying, machining parts,and removing and installing. Or cleaning the dyno cell of what seemed gallons of Valvoline 20-50 racing oil. ( More to come on that.)

Heres the cell after 2 hrs and 4 guys cleaning oil off the ceiling, walls and everywhere.

Some of the highlights.

Fuel Used

54 gallons of 93 octaine, 100LL Avgas, and 104 octane racing fuel.

Oil

4 cases (48 quarts)

Oil Filters

11 Filters used (various types)

47 separate engine pulls

Well I gotta get going for now but we did 4 pulls with this stuff

Let me tell you, has anyone seen a 401 AMC turning a 30 old crankshaft and inputting 900 ft lbs of torque on two bolt mains?

It's damn scary

Heres a vid

http://www.youtube.com/watch?v=DmvzACSpQVM

Jeff

Reply With Quote

Reply With Quote

(cool stuff at the shop also!!!)

(cool stuff at the shop also!!!)