Well, most of the cam manufacturers rate cams with that much duration in the 1500 and up RPM range, with peak numbers near 4000 rpm, and generally recommend an increase in compression ratio to around 9.5:1. With stock compression and gears, I would expect low end to be pretty anemic with something like that.Originally Posted by jeepsr4ever

The Summit 8600 cam has a very late intake closing point (65ABDC) and 53 degrees of overlap, neither of which are good for bottom end torque.

For comparison, don't forget donwags 401 with 9:1CR running a Comp XE256, 212/216 @.050 and only 54ABDC intake closing point with 42degrees overlap - made over 400ftlbs from 2-4400rpm with peak torque of 428 at 3400 and 348hp at 4800 on the dyno.

401's have a higher intake valve size to displacement ratio but more dwell time than a 360, so neither need a lot of overlap to make good power.

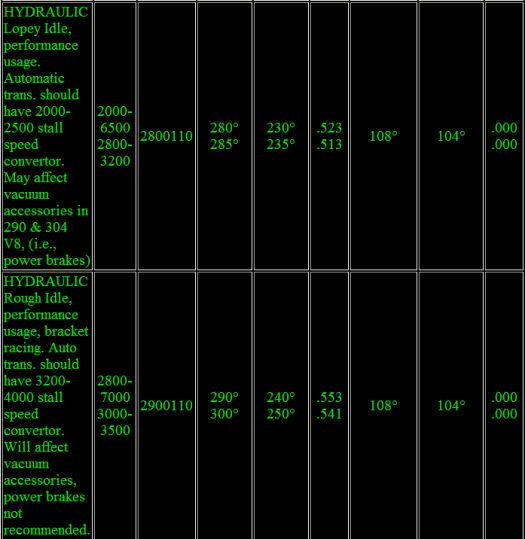

Remember that all duration does is shift the point at which peak torque is produced around 500 rpm per each ten degrees of duration - the downside is that too much overlap and a late intake closing point makes bottom end power evaporate.

Anyway, not saying the 8600 won't run in a 360 and may even be better than stock, but I doubt it is the best you can do - especially not without a bump in compression and some taller gears to let the engine rev up quickly.

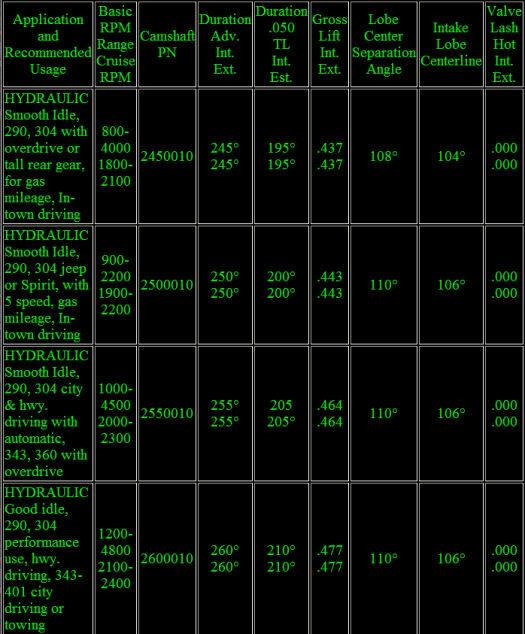

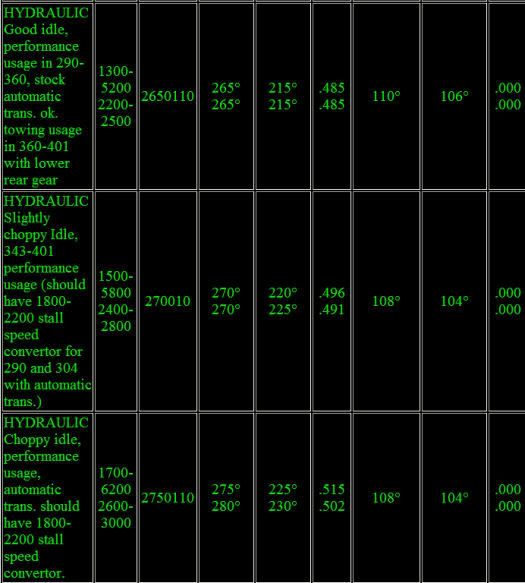

First piece of advice before choosing a cam should be to analyze seriously what RPM range you are really operating in. Do you really rev over 4000 rpm consistantly or are you typically cruising in the 2000-2500rpm range? Are you willing to increase gear ratio to raise engine speed? Are you willing to accept the decrease in fuel milage that comes with higher rpm operation? Will you change pistons to raise CR? Do you have a free flowing exhaust system? Bet most Jeep operators would do better with lower duration cams.

Reply With Quote

Reply With Quote