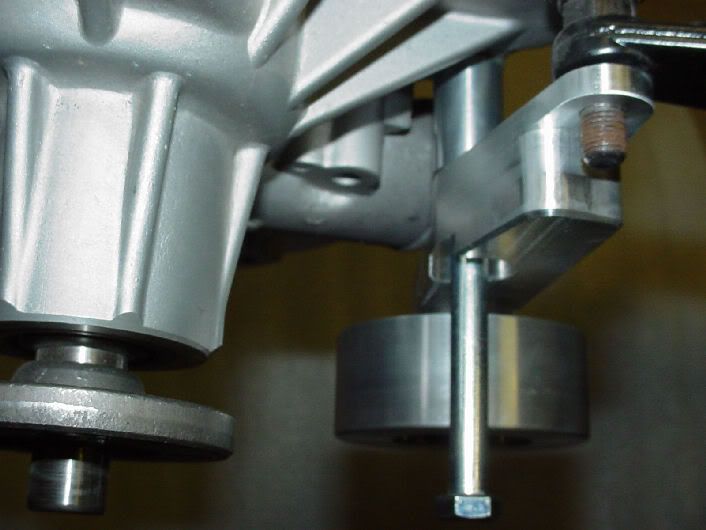

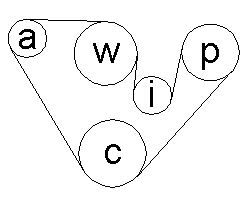

AMC V8 Serpentine belt system is shown here. It utilizes a 78.50" 6 rib one sided belt (Part number #4060775 and 4060763 for 10% under-drive). System also utilizes the 707 alternator relocation bracket kit (supplied in the Serpentine kit). The factory power steering and water pump stud is required for proper assemly. The crankshaft pulley is available in stock and 10% under-drive diameters.

Kit includes

1. Custom Poly V crankshaft pulley (stock or 10% under-drive)

2. Custom Poly V water pump pulley

3. Custom Poly V power steering pulley (available in press-on or keyway style pumps)

4. Custom Poly V alternator pulley (available in 5/8" key way or .669 slip fit)

5. 707 alternator relocation bracket assembly

6. Smooth 2.875 Idler wheel

7. 1" thick Idler wheel bracket

8. Assembly hardware

Reply With Quote

Reply With Quote