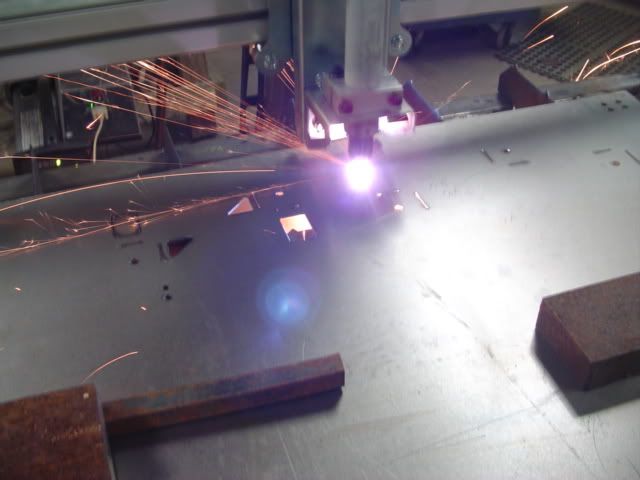

Been making brackets for the cable carrier, the machine is reproducing. ;)

its the raw steel one

complicated to wiggle around the 2 motors and stuff. motors removed for fit up.

bending it up

you only have to run the carrier from the mid point of the travel, I bought a little extra to make the run right across.

It was $195CAD including $50 shipping, for 10' and two mount kits. not too bad, its high quality stuff, looks great and works really smooth.

wires all in

Now I will move to the other axis and run a cable carrier down the side.

Reply With Quote

Reply With Quote

Dont be afraid to run your table by the book. Check the other posts in this area for book speeds.

Dont be afraid to run your table by the book. Check the other posts in this area for book speeds.