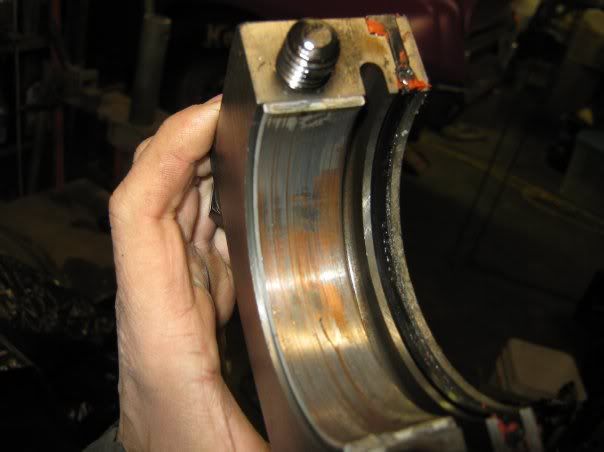

ok so i am going to post some pictures of the couple sets of cam and dizzy gear that got chewed up in my motor. I know that oilling was not the issue because i had between 40psi at idle and 80psi at high rpm and i had the little hole drill above my dizzy for extra oiling

so my question is what else could have caused this. if i order the matched cam gears and new timing cover from bulltear will that fix it? i use a msd dist ( the amc style one).

these two were a set both amc brand gears

and these two were a set the dizzy gear was msd and the other one cam with the motor

the first set lasty say 5 or 6 pass down the track and the second last 10 -15 can exactly remeber

i hope you guys can give me some help in figuing this out

thanks justin

Reply With Quote

Reply With Quote

I did have the oil pressure spike and blow the oil filter gasket but I think the plunger got stuck with crap from the gears going bad. Anybody pull the pan and look at the mains & rods after chewing a set of gears??

I did have the oil pressure spike and blow the oil filter gasket but I think the plunger got stuck with crap from the gears going bad. Anybody pull the pan and look at the mains & rods after chewing a set of gears??