So today we got the water table almost finished! We decided on 5 inches deep. Tomorrow we will grind down the welds and check for any weak spots.

Okay, we are getting ready to hook up the electronics to our cutter. Would love any help that we can get!! Please & thank you.

Matt - Any luck with some pics of the new gantry setup so we can check our work. Also, when we attach the machine torch & torch mount to the breakaway plate, it will fall off with the slightest of movement...? Any suggestions? Thanks.

You may have to zip tie your machine torch lead to your cable carrier. The cable carrier will pull the torch. If you are still having trouble after trying that pm me please. In the next 2 days we will have very nice pics up. Sorry its taking so long we had some boo boos in mfg that is pooling all our guys.

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689

Let me know how that works. It should already be in the instructions. If not we will add it. The problem is the torch lead is strong enough to overcome almost any magnetic pull.

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689

Thanks Matt. Where do I find those instructions?

Hows it going?

So we have moved the air compressor into the new shop, wired it and started piping it. Wired the air dryer. We have finally got the warping out of the water table...

Matt,

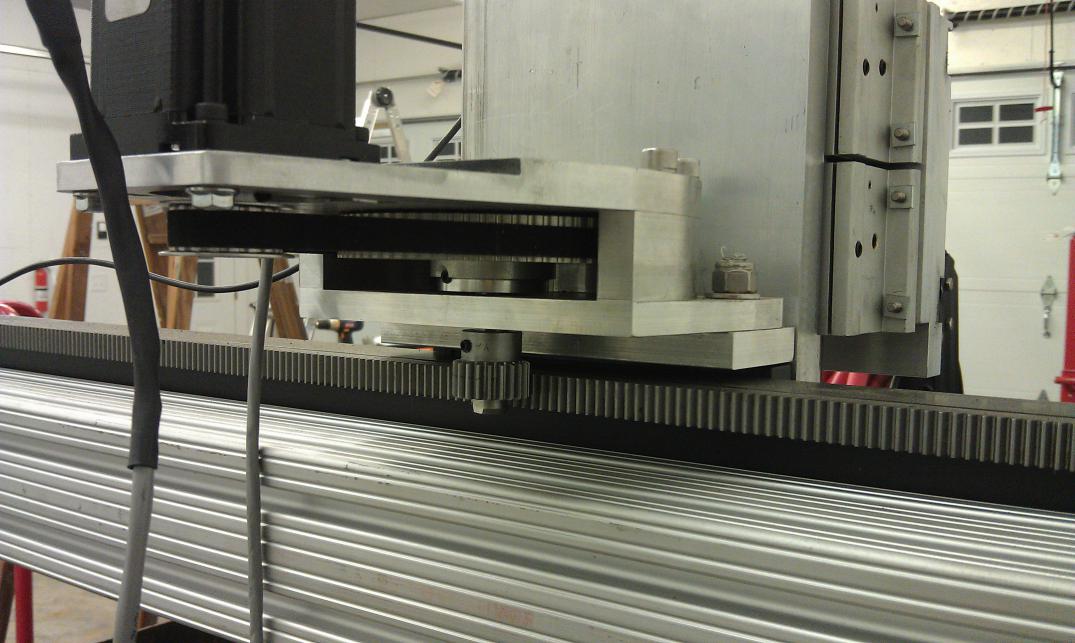

Here are the close ups of the gantry & stepper motors. Does everything look like we put it together correctly?

You need to move your ear into the width of the gear rack on all axis. Push the gear into the gear rack while tightening the nuts on the studs that are going through the motor bracket slots. You have it right though there is no other way to install the brackets. It was designed that way with the A axis and X axis mirrored. It makes for a lot more machining and mfg but they cannot be installed wrong.

:( That aluminum gets dirty quick even by the hand touching it.

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689

Oh and it looks like you didnt install the SAE stainless steel washers under the locknuts on the motor brackets.

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689