Your Z is correct for the steps per. I wouldnt say its adding yet. It could be a sticky switch for Z home.

Your Z is correct for the steps per. I wouldnt say its adding yet. It could be a sticky switch for Z home.

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689

Which post processor are you using for sheetcam...should be MP1000-THC only for plasma.

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689

I dont think this would matter there isnt a post that would cause this after running through them. Go to diagnostics in Mach 3 and push the Z up until the Z home lights up. Repeat this until you feel a bind or see an error. The tolerances are pretty tight on the Z axis and I can imagine anything binding up. I wonder if its a switch issue.

You said

This would indicate a bind in the Z axis to me. This means the Z is held up and the home switch is activated too high. It wouldnt take much to hold up the Z axis. More common is the torch cable coming in contact with the upper Z axis linear support and thrust bearing mount. Its the top piece of 3/4" thick aluminum and if the torch lead hits it sometimes it will give the Z axis a false height reading as it holds up the Z. The lead needs to be free.On one pierce it actually touches the material, zeros, pierces correctly and cuts the part. The next time the Z will go down to touch off but stop midway (not even close to the material) zero, then go to pierce height, which ends up being way to high of the material to even pierce. Its almost like the Z looses track of position. I have also had the Z bury it self into the material in the middle of cutting (thanks for the breakaway) Any suggestions

The Z axis burying itself into the cut means your not reading tip volts correctly. Also what is your velocity and accel numbers for Z?

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689

I have looked at the Z, dis-assembled, reassembled it, I don't feel that it is sticky

I have tested the switch and ran the Z up and down a thousand times while watching the Z home light. I only see it light up when the torch is indeed home, and never seen it stay lit up.

Yes, MP1000-THC. There is a post I thought of trying....MP1000-THC-Zref....but only because it said Zref in it.

I have lots of slack in the torch cable in order to not let it get caught in the Z.

Per your specs.....Velocity 800, Accl 40

Velocity 50-80, accel 15 on the Z axis

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689

If I run it with THC off, so its not looking for volts or anything. It will keeps adding up the Z movements. Out of 4 pierces, the first starting at .16", then the second at .about .19, the third at about .4, and it tries to to do the final one around .55". Somehow it is adding up somethign.

Something triggered z home. It could be that your ref distance in sheetcam (the distance between touch offs) was in play and you started on top of a piece of warped material, made a small cut then went to the other area that was warped the other way and the torch fired a little too high. How high was it off the plate? For it to fire off the plate the Z home switch needs to be activated. The only way this can happen it is the Mag-Lok is held in position while the Z is moving downward. If you continue to test it and you cannot find an issue I would say it was held up by the torch lead a couple of times. If it rubs on that top plate this is what may happen. Also Z home only lights up when you push UP on the Z axis and should never stay on. I think your good to go on that part.

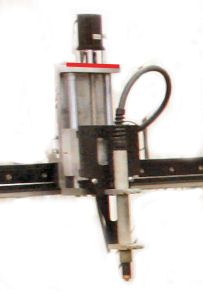

In the red area is where the torch lead sometimes catches if your lead isnt positioned like this one.

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689

This isn't a every once and awhile occurrence, this happens every single time I try to cut.

I have brand new 4x8 sheet of .25", and have tried to cut in several areas of the sheet. I get the same results, so its not due to the plate warping.

The overall height will stack up through the pierces and cuts, the whole time the DRO will display the proper values, but the torch will be higher up to .4-.5" off .

I know what you are saying that if the Mag-Lok is being held up. I can almost guarantee its not. I can hear when it hits the switch...even when cutting and there are times it wont hit the switch, but will zero the DRO and go to pierce height.

Here is my torch cable...no way its getting in the way. Edit> The picture is deceiving, but the cable is about 3" away from the aluminum

I also disabled the Z home in Ports and pins. I manually Zero the Z at the work surface, and run the program, and it does the exact same thing. Starting to think its something with Sheecam, the post, or the Gcode

Can you copy and paste your G-code? If it isnt in the G-code and it isnt in the hardware then it could be a Mach issue. During normal operation Mach will wait for the signal for Z home then start the whole pierce dialog. This is done by a G92 code in which Z travels in the negative direction until it gets a signal from the I/O board saying Z home has been activated. These machines use that little microswitch for this. It is possible that you are loosing this switch from a loose wire (most likely and has happened before). Either on the switch or on the connection to the I/O board. Go to diagnostics and have someone wiggle the wire on both ends (Z axis and control box) and see if the switch lights up.

N0070 (Process: No Offset, Default, T1: 1/4 steel)

N0080 M06 T1 F45 (1/4 steel)

N0090 G00 Z0.9000

N0100 X12.0249 Y0.7852

N0110 Z0.2500

N0120 G28.1 Z0.12

N0130 G92 Z0.0 Touch off

N0140 G00 Z0.0520

N0150 G92 Z0.0

N0160 G00 Z0.2500

N0170 M03

N0180 G04 P0.2

N0190 G01 Z0.1100 F60.0

Last edited by jeepsr4ever; 05-06-2012 at 11:19 AM.

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689