we received the 4x8 turnkey plasma table last week. i will document the set up and run off here.

we received the 4x8 turnkey plasma table last week. i will document the set up and run off here.

first off. no instructions, no documentation.

where do i find manuals? are they in the pc?

where does the thc sensor pmw hook too?

it came in a bag with a plug that matches the cpc port on the powermax 65.

the dcp port looks like a phone cable and there is a ethernet port on the side.

there is an ethernet cable in the box.

what does it plug into?

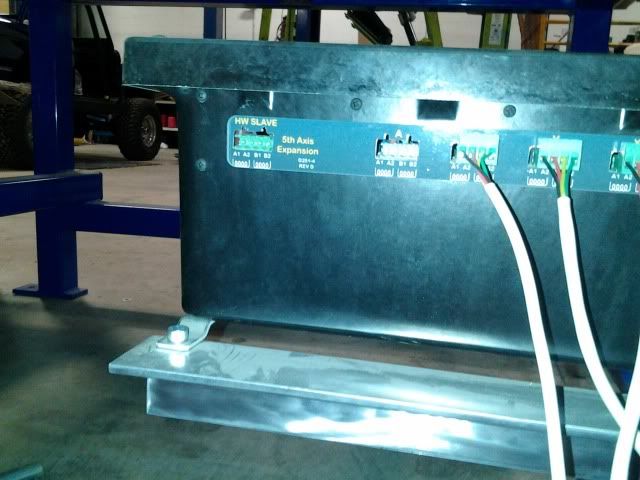

i have 2 cables: 'A' from the rotary table i assume plugs into the 'A' port on the control box.

also a cable marked 'B' does this go into the 'HW slave' port? the only available plug.

Last edited by _Ogre; 12-20-2013 at 05:41 PM.

how close can the powermax65 and the pc be located? same table/bench/cart? 5 ft away?

can the plasma cable and the control cables; serial and printer cables, be run together without causing interference?

got the rotary table mounted today. have no chuck key for the chuck, can you send us one?

Last edited by _Ogre; 12-20-2013 at 06:22 PM.

There should have been some videos on the desktop. A goes to A axis and B to the Aux. There is also support files on the desktop. Ethernet connects to PWM to big black box and does not go to the PC. DCP is not required and you have the two cables hooked up correctly. They can all run together no problems. The plasma should be at least 3 feet away from the big control box. Thats great you got the rotary table mounted! They are very heavy!

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689

after posting those i found the manual on the cancnc site. that explained most everything.

also found all the manuals on the pc that i hadn't hooked up yet.

got all motors to jog today. baby steps.

rotary table is heavy for sure

bearings look like could be for a battle ship prop shaft.

just did a test of our new bulltear 4x8 w/ dthc, mach3 bladerunner and powermax 65. the torch fired and cut the shapes i had drawn; just out of scale. i am fairly well versed in autocad 2000 and use it for all technical drawings the drawing is in inches. i had drawn simple shapes ''plasma test'' 2- 2'' circles and 2- 2'' squares and an arc thingy. the circles and squares cut great, they were just 4.5'' across instead of 2'' as drawn. any ideas of what i did wrong?

plasma test

this might be a sheetcam tng problem but i'll post it here too:

so i moved on to my first real project. ''mrt bronco3'' is a couple of simple signs to be cut out of 10 ga mild steel. it took me a few times to get all of the arcs drawn to make 1 pierce per letter, when i run sheetcam it has the outside of one sign cut first then the letters. then sheetcam jumps around cutting some letters in the 2nd sign then some letters in the 3rd sign, then the outside of one sign and then the rest of the letters. how do i move pierce point and the layout of the cuts?

plus i'm a little leery of cutting these out until i get the scale thing figured out.

mrt bronco3

also can any one tell me how to do a test draw? or test the cut path without the torch on?

i tried to run the gcode in mach3 with the torch off and z axis zeroed out one half inch above the water table slats. the z axis went past zero and traveled below the slat surface.

received the software disc and the thumb drive. thanks for the backup files.

what files do i need to back up to save all the profiles that the machine came loaded with?

one last thing today; how do i use the play station controller?

i have it plugged into a usb port but it controls no motion at this point.

If your cutting oversize a setting is off. Call in when you can someone here will take care of it for you. You should be next to the PC with Mach running.

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689

thanks for the phone setup help mc. ran the test piece to the correct scale after that.

what files do i need to back up to keep those settings?

the game controller makes life easy peasy too. nice jog/start/stop functionality.

i've read everything in the forum for setting up the table, there's not much on the rotary head.

want to try that out next. can you send me some links or info on the rotary head?

also any way to dry cycle the machine? test run on pieces with out the torch on.

bulltear 4x8 turn key table w/dthc, rotary tube cutting head, mach3 bladerunner, hypertherm powermax 65

XML file in Mach3 called Bladerunner and Bladerunner rotary. Dry run with plasma off by pressing torch on/off after initial touch off. Rotary is setup to use no limits or home switches. More soon!

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689