tried the rotary head today with out any luck. loaded a cope program in the rotary mach3 program. the y axis took off, y axis should be centered on the tube and all cutting done with x and a axis. tried the tube cut program y axis took off again. so quit that and left you a voice mail. i'll try to call bulltear on monday.

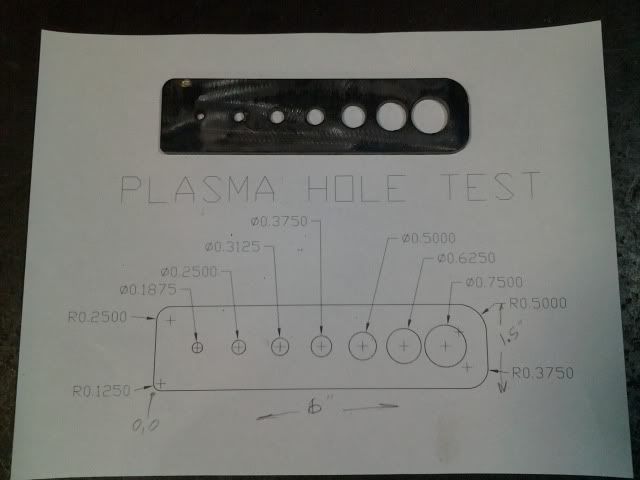

on the plus side... table is working well. cut the mrtbronco4 door roll bar signs and a receiver mounted 3rd brake light cover for the 66 bronco we have in the shop. also cut out some hole test and line test drawings. everything working well. thumbs up on this table. :D

mrtbronco4

line test (drawing not to scale)

hole test (drawing not to scale)

did some testing on cutting holes in 16 ga 304 stainless exhaust tube just using the x,y,z axis's and the dthc with moderate success.

this is for welding in the H on an H pipe exhaust; normally we'd use a 2.25'' hole saw at $12 per for maybe 10 holes (5 systems)

had to use settings for 10 ga steel to complete the cuts down low. lots of dross, but it's easy to clean off.

the holes are 2.25''x1.75'' elliptical

hoping to get the rotary head going on monday to cut out the actual H pieces

Reply With Quote

Reply With Quote