what post processor do I need in sheetcam to run plate marker/scribe? I see some there but not sure if they are the right ones.

what post processor do I need in sheetcam to run plate marker/scribe? I see some there but not sure if they are the right ones.

The standard post you are using will work. You may have a tool (Tool 101) that may be an air scribe already.

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689

The post you have been using for flat cutting also control the scribe. So if you go to Sheetcam/Options/Machine/Post processor/edit then put in these offsets for the scribe.

X -14.265

Y -59.18

Z 10.

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689

Ok i found it and got the x and y done but have some trouble geting z offset perfect. X and y seems good but z is either to low or high. Maybe im not doing it right to get the correct mesurement. I drop the torch down and make contact with the plate and zero z in mach. Raise the torch engage the air slide scribe and then lower the z travel till the scribe contacts the plate. Take that measurement change to mm and enter that number in the post processor. Am i doing that correctly?

Thanks gary

The air cylinder on the scribe is what sets the Z depth. Youll never be able to use an air scribe that is rigid mounted without a slide and air cylinder and a torch at the same time.

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689

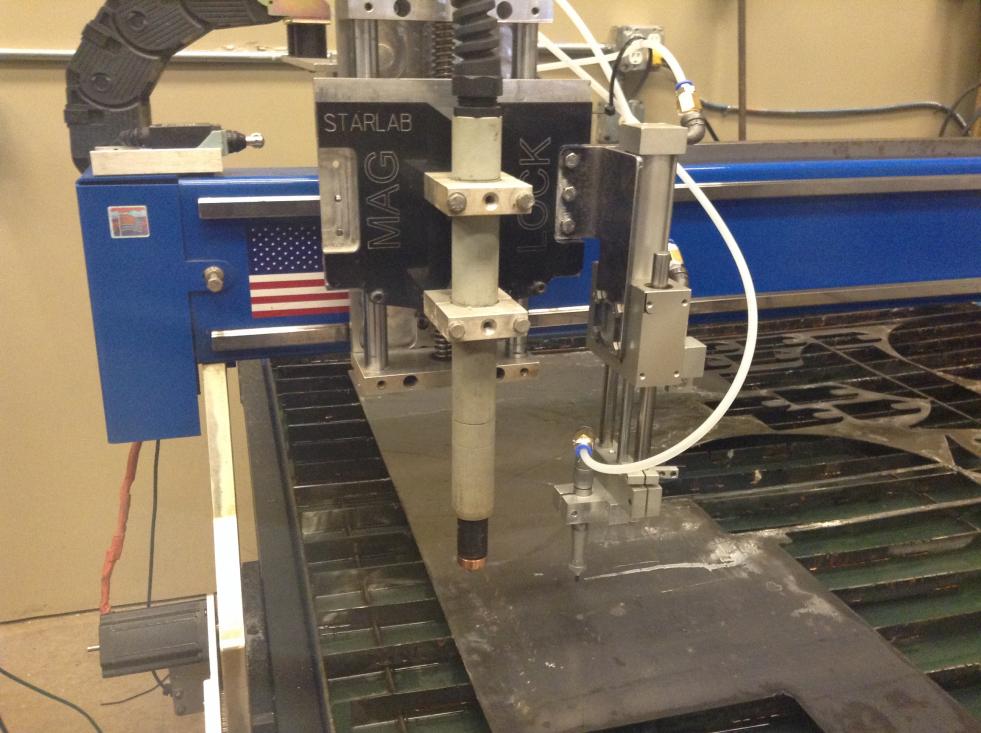

I have a 4x4 bulltear table, using sheetcam, and mach3 . the control box is a candcnc espII-A. I have a floating head with a magnetic mount for the torch and a the scribe is on a air slide that is on a rigid mount on the Z plate floating head. I'm not sure if I built it right cant seem to find a lot of pictures or descriptions on this.

Thanks gary

When you boil it down you only need 1 5 way valve and 2 regulators. Your post is not set up to turn on both outputs at the same time.

[COLOR=#000000]

Featuring www.StarLabCNC.com[/URL] for CNC plasma machines

1-651-433-3689 TOLL FREE 1-855-433-3689