AMC friends,

I built a 360 last year, and threw a rod through the oil pan a few months ago. I had just changed the oil after a few hundred miles and added zinc in as prescribed.

10 minutes later I was working on carb tuning and blipped the throttle on the gas pedal with my hand, and it overrevved and the damage happened. I didn't feel like I had revved it that hard, felt more like a tap.

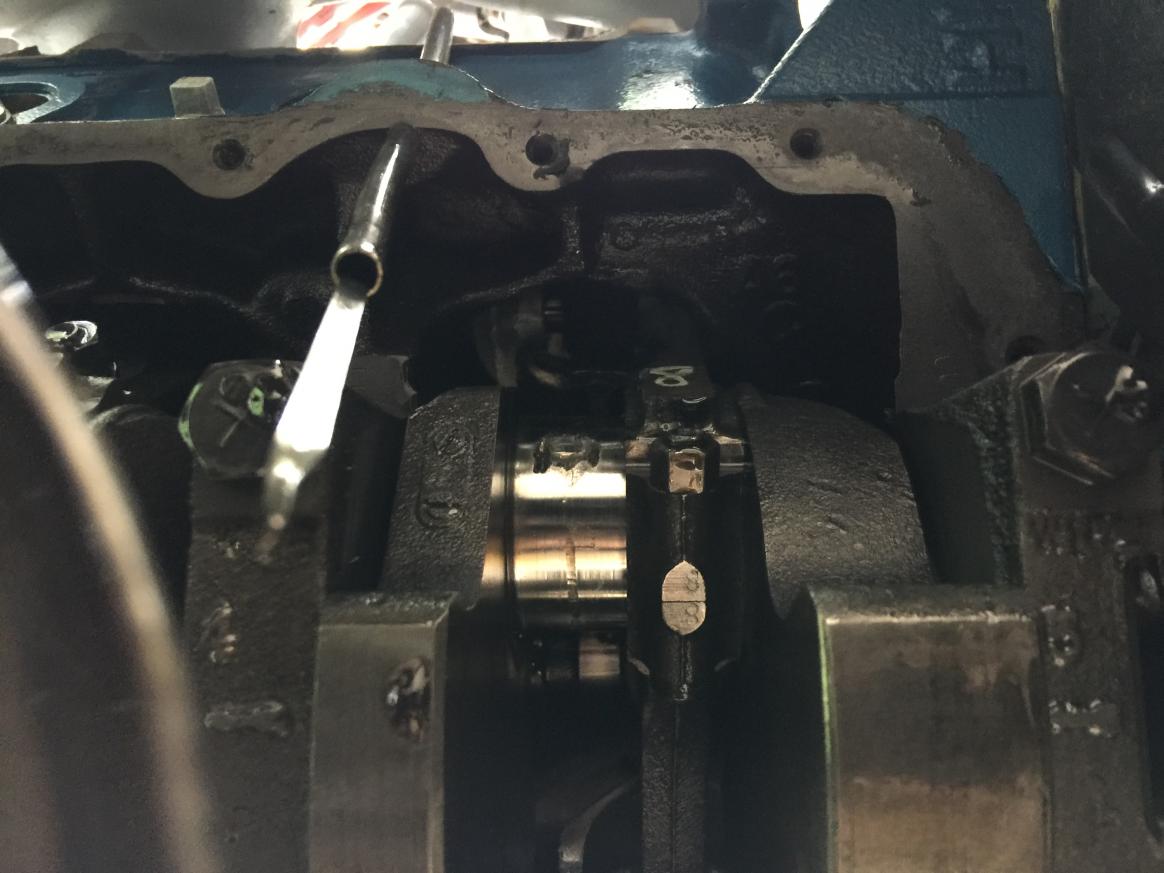

Good news: block from what i can see is ok. Crank has bad scarring.

Questions: could the ZDDP addition have something to do with it? What could I have screwed up on the build? Are the cast iron rods weak? (all parts were checked at machine shop pre-assembly)

Reason I'm asking is that I'm going to rebuild in the fall. I'll have machine shop go through it again, will likely need a new crank. Would love advice if I missed something so I don't repeat my mistake. Thanks!

Shawn

Reply With Quote

Reply With Quote